-

OverviewSuper Clear PVC Film for Rainwear provides exceptional transparency combined with robust performance, makin...

-

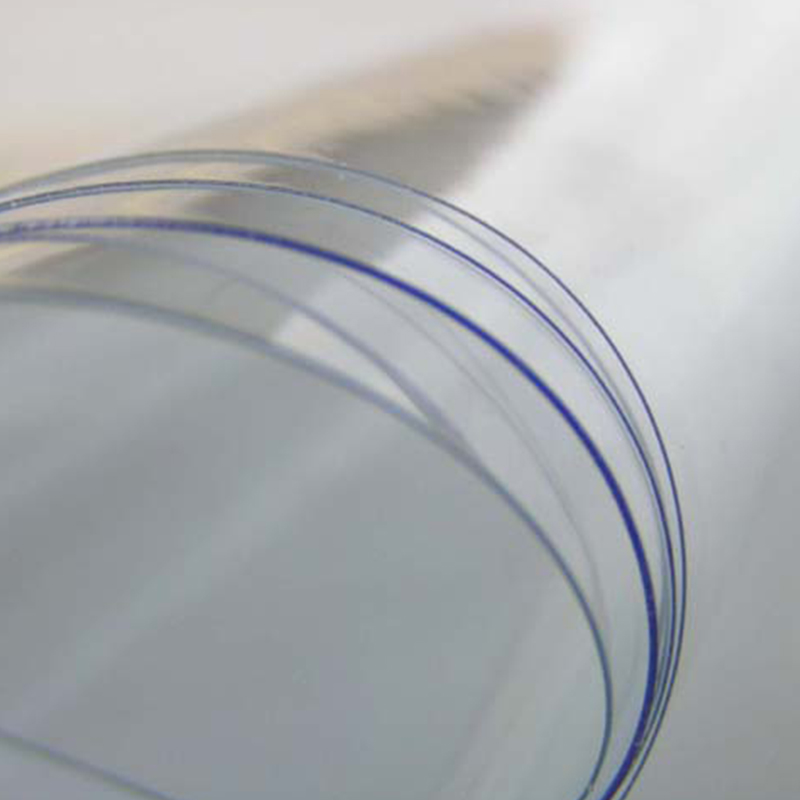

OverviewOur Super Clear PVC Film for tablecloths offers ultra-transparent protection while maintaining a sleek appe...

-

OverviewReliable clear PVC film featuring a powdered, non-sticky surface and slightly lower clarity. Key FeaturesFu...

-

OverviewSemi-transparent PVC film with matte finish, delivering light diffusion and a refined tactile feel. Key Fea...

-

OverviewDecorative yet functional embossed PVC film combining color and surface texture for protective book covers....

Uses And Classification Of Transparent Packaging Films

Transparent packaging films have become a cornerstone of modern packaging solutions, offering both functional and aesthetic advantages across industries. These films not only protect products but also enhance presentation, ensure safety, and maintain hygiene.

Uses and Applications of Transparent Packaging Films

Transparent packaging films are versatile materials that serve multiple purposes in packaging. Their applications can be broadly categorized into protection and securement, beautification and anti-theft, and food and pharmaceutical packaging.

1. Protection and Securement

One of the primary roles of Transparent Packaging Films is to protect products during storage and transportation. Packaging plastic film offers a barrier against dust, moisture, and water, preventing contamination or degradation. These films also stabilize products by tightly wrapping them, minimizing displacement or movement that could result in damage.

- Heat sealing and wrapping: Transparent films can be heat-sealed around products, forming a snug, protective layer.

- Stretch and retraction properties: In industries such as tobacco, textiles, and automotive components, packaging film is used to secure irregularly shaped items. The elasticity of Transparent Packaging Films ensures that uneven forces during handling do not harm the product.

- Industrial applications: For example, rolls of fabric, car parts, and tobacco packs are often secured with packaging plastic film to maintain product integrity during shipping and warehousing.

By providing these protective properties, Transparent Packaging Films reduce product losses, enhance durability, and contribute to cost-efficient logistics.

2. Beautification and Theft Prevention

Beyond basic protection, Transparent Packaging Films enhance product presentation. High transparency allows consumers to view product details without opening the package, making it ideal for retail applications.

- Self-adhesive packaging: Many packaging film variants feature self-adhesive properties, allowing products to be sealed securely without secondary packaging.

- Anti-counterfeiting and theft prevention: Self-adhesive packaging plastic film can integrate tamper-evident features or holographic elements, making it difficult for counterfeiters to replicate.

- Retail appeal: Products such as clothing, masks, and small consumer goods benefit from Transparent Packaging Films because the clear surface showcases quality and design while providing protection.

Through these functional and aesthetic benefits, Transparent Packaging Films improve brand visibility and enhance consumer trust.

3. Food and Pharmaceutical Packaging

The food and pharmaceutical sectors rely heavily on Transparent Packaging Films for their barrier properties, flexibility, and hygiene. Packaging plastic film can protect sensitive goods from contamination, moisture, and oxygen exposure.

- Food applications: Products such as beverages, frozen foods, and packaged snacks use packaging film to maintain freshness. Some films, like LDPE or BOPP, are used directly for wrapping or as part of composite multilayer structures.

- Pharmaceutical packaging: Tablets, syrups, and medical devices are often enclosed in Transparent Packaging Films, which maintain sterility while allowing product visibility.

- Aluminum-plastic replacement: Certain composite packaging plastic film solutions can substitute traditional aluminum-plastic laminates for meat and dairy products, offering better transparency and easier recycling.

The adaptability of Transparent Packaging Films for high-barrier, heat-resistant, and flexible packaging makes them a critical material in the food and pharmaceutical supply chain.

Classification of Transparent Packaging Films

Transparent packaging films can be classified based on the material used and their functional characteristics. This classification helps manufacturers select the right packaging film for specific applications.

1. Classification by Material

- LDPE (Low-Density Polyethylene):

LDPE is highly flexible, water-resistant, and widely used in food packaging. It accounts for over 40% of packaging plastic film usage. LDPE films are ideal for wrapping delicate items such as bread, fresh produce, and confectionery.

- BOPP (Biaxially Oriented Polypropylene):

BOPP is commonly used as the outer layer of composite films. It offers high transparency, outstanding mechanical strength, and resistance to puncture. Many retail products, including snacks, confectionery, and textiles, rely on BOPP Transparent Packaging Films.

- PET (Polyethylene Terephthalate):

PET films are high-temperature resistant and mechanically strong. They are suitable for vacuum packaging and other applications requiring durability and heat stability. Packaging plastic film made from PET maintains clarity and structural integrity even under demanding conditions.

2. Classification by Function

Transparent packaging films are also classified according to their functional properties:

- High-Barrier Films:

Nanocoating or multilayer construction enhances the oxygen, moisture, and aroma barrier properties. High-barrier packaging film is used in aseptic packaging, such as milk cartons and ready-to-eat meals.

- Retort Films:

These films are engineered to withstand high-temperature sterilization processes, such as 121°C for retort packaging. Retort-resistant Transparent Packaging Films ensure the safety and shelf-life of canned and ready-to-eat foods.

- Laminated Films:

Combining plastic and metal layers, laminated packaging plastic film provides enhanced resistance to light, moisture, and oxygen. Aluminized laminated films are commonly used for snacks, coffee, and meat products where both protection and shelf-life are critical.

- Self-Adhesive and Decorative Films:

Some packaging film variants include self-adhesive layers or printed designs to enhance branding, visual appeal, and tamper resistance. These films are especially common in consumer products, from apparel packaging to electronics accessories.

Advantages of Using Transparent Packaging Films

- Visibility and Consumer Trust:

The transparency allows consumers to see the product directly, which increases confidence in quality and authenticity.

- Protection and Durability:

Packaging plastic film shields products from dust, moisture, UV light, and handling damage.

- Flexibility in Design:

Transparent films can be laminated, printed, or combined with other materials, allowing customized solutions for branding and functionality.

- Cost-Effectiveness:

Compared to rigid packaging, packaging film is lightweight, reduces shipping costs, and simplifies storage.

- Environmental Considerations:

Many Transparent Packaging Films are recyclable, especially mono-material LDPE or PET films, offering a more sustainable packaging option.

Emerging Trends in Transparent Packaging Films

In addition to traditional uses, Transparent Packaging Films are increasingly being engineered for smart packaging solutions. Packaging film now often integrates anti-fog, anti-static, and antimicrobial properties to improve product safety and shelf-life. For instance, packaging plastic film with anti-fog coatings is particularly useful for chilled or frozen foods, ensuring clear visibility without condensation. Some Transparent Packaging Films also include tamper-evident or QR-coded layers to support traceability and consumer engagement. The adaptability of packaging film makes it suitable for automation in high-speed production lines, while packaging plastic film continues to evolve to meet both sustainability targets and advanced functional requirements in modern packaging.

Transparent packaging films are an indispensable part of modern packaging, serving multiple roles across industries. From PVC Decorative Films used in food, pharmaceutical, and consumer goods, to high-barrier, retort, and laminated films, packaging film provides protection, visibility, and aesthetic enhancement. The classification of films by material and function allows manufacturers to select appropriate solutions for their specific application.

By combining durability, transparency, flexibility, and protective properties, packaging plastic film ensures products remain secure during storage, transport, and retail display. Its role in beautification, anti-theft measures, and barrier protection makes Transparent Packaging Films one of versatile and widely used materials in contemporary packaging.

English

English русский

русский Español

Español عربى

عربى